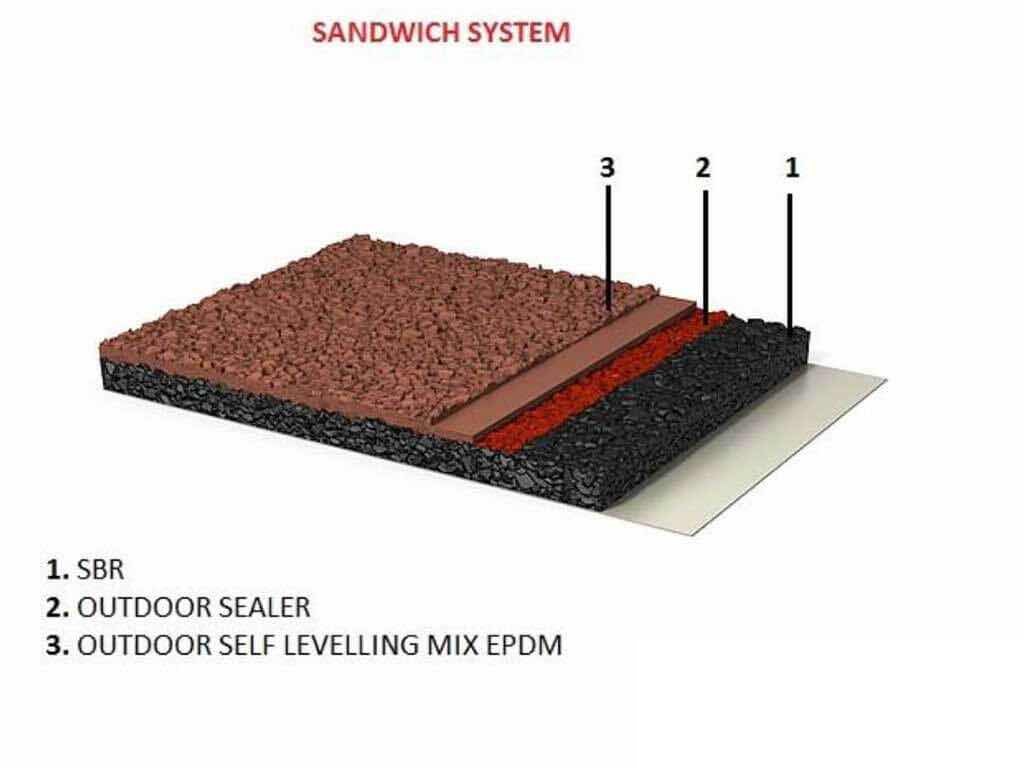

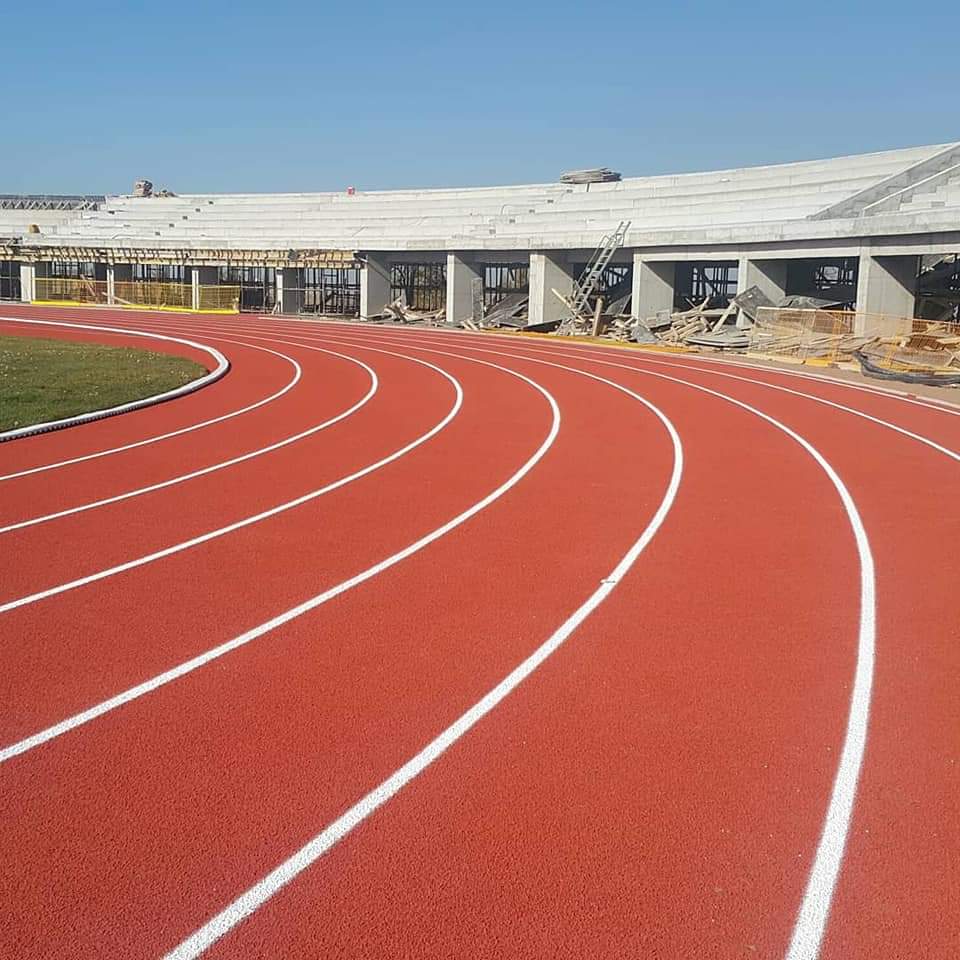

POLYURETHANE SANDWICH SYSTEM FLOOR COATING

For outdoor use on running tracks, sports fields and athletics fields It is one of the polyurethane flooring methods. System; primary, elastic The layer consists of a polyurethane layer and EPDM layers.

It is an IAAF certified flooring system by World Athletics.

Product Features:

Layers

Primary

100-160 gr / m²; 1100 cp; 1.03 kg / L

Granular Rubber

SBR Granule (100 units); 8500 gr / mm2; 1-3 mm

Polyurethane Binder

Polyurethane Binder (20 units); 8.5 kg / m2; 3000-3500 cP; 1.1 kg / L

Outdoor Putty

1031 gr / m²; Mixing Ratio: 18/2; 35000 cP; 1.68 kg / L

Outdoor Self Leveling

2400 gr / m²; Mixing Ratio: 5/4; 4320 cP; 1.16 kg / L

Colored EPDM Granules

3.2 kg / m²; 1-3.5 mm

Mechanical Test Results

| Features | Results |

| Shock Absorption | 38% |

| Thickness | 13 mm |

| Vertical Buckling | 1.5 mm |

| Friction | 58 |

| Tensile Strength | 0.53 MPa |

| Elongation at rupture | 46 mm |

Application:

Surface Preparation

The floor must be clean, dry, free from oil and dust and repaired.

Method of Application

A one-component polyurethane primer is applied on a floor that is free from dirt, oil and dust. After it dries, it is mixed in a mixer with 100 units of SBR granule and 20 units of polyurethane binder and applied to a surface of 10 mm height. 18A and 2B ratio paste is mixed and SBR is applied to the layer. After the paste dries, a self-leveling material consisting of 5A and 4B components is applied to the surface. Finally, brick-colored EPDM granules are applied by sprinkling on the polyurethane self-leveling layer. Excess EPDM granules are swept away from the surface after it is completely dry.

Application Conditions

After mixing the two components in polyurethane putty and self leveling, they become ready to use. Hot environment shortens the usage time and increases the cold environment usage time. It is not recommended to be used at temperatures below 10 ° C. It is also not recommended for use at temperatures above 30 ° C.